The technology of creating do-it-yourself furniture from cardboard, and visual diagrams and patterns. The technology of creating do-it-yourself furniture from cardboard, and visual diagrams and patterns Model of a house made of wood

Despite the fact that most computer programs that run in 3D modeling allow you to quite realistically imagine the appearance of your future home, the layout of paper houses is still relevant. After all, not all of these programs own. And ordering such a computer model for an experienced engineer or designer is expensive. In this case, mastering simple techniques for modeling paper and cardboard houses is much faster.

And if you have children from 2 to 10 years old, then this work for them can turn into a fascinating activity. Moreover, the training and developmental effect of this type of activity is difficult to overestimate. Here and accuracy, and motor skills, and skills in working with tools and, of course, the development of spatial thinking.

Simple layouts of paper houses and reamers for gluing

Making a house layout with your own hands is not difficult. The simplest paper house layouts are easiest to make from the so-called. developments, when all their elements are interconnected by fold lines and represent a single element in the form of a diagram.

Also, the scan, in addition to walls, floors and roofs, has additional bends for gluing. On the Internet you can find links to such scans. It is enough to print them on a printer or, having measured the aspect ratio, draw them on sheets of paper or cardboard and get a scan scheme for modeling.

You can transfer the resulting scan onto colored paper.

Using a needle or an awl, you can transfer the key points of various elements to it: windows, doors, attachment points for additional architectural elements, and so on. You need to cut them out immediately with a clerical knife, placing a piece of thick cardboard or plywood under the scanned sheet.

Overhead elements are made separately: window frames, shutters, doors, etc., which you will stick on the finished layout last.

An even bend along the lines is easiest to do by attaching a ruler with a sharp edge to it. By repeating this procedure in all places of the bend, you will get a scan ready for gluing.

You can also make a scan by making each structural element separately, and connecting them to each other at the fold points from the inside with adhesive tape. This method is especially interesting when you are making a model of a house from thick and hard cardboard.

You can glue the layout using fast-setting adhesives such as PVA, stationery silicate, glue stick, etc. You can also make it using double-sided tape, sold in hardware stores.

Here is a video to help:

We make a sweep for the layout of the house with our own hands

The process of self-manufacturing reamers is no less exciting than working with their finished samples. To do this, you will need almost any program for working with graphic images installed on your computer. CorelDraw or similar, which processes vector images, is best. In it, with an increase or decrease in the size of the image, both the line thicknesses and the loaded textures change in the same ratio. This allows you to get more realistic images. And the library of textures built into its shell itself is impressive. At the same time, by filling the scan element with a texture, you can get the finished appearance of the main elements of the layout.

The whole process, including filling parts of the scan with the selected texture, applying visual effects and architectural elements, and inserting images from the symbol library, takes from 10 minutes to half an hour if the house is not very complicated. Print a scan on a color printer and start layout.

For testing, you can use this one, made by us, by copying the image to a computer and enlarging it to the desired size.

Making complex paper layouts

The process of manufacturing complex multi-component house models does not differ much from that described above. It's just that similar sweeps are also performed for individual elements of composite layouts. A group photo of the assembly of such a layout shows its individual elements and the assembly order.

Having mastered the simple technique of making simple paper houses, you can create entire paper towns with landscape design elements, plants, car models and small architectural forms.

The easiest way to make layouts of buildings from paper of a round shape is to apply the formula for determining the circumference (2πr) to their calculation, adding a strip for gluing to it.

You can also add realism to your layout by making a simple illumination of the house from the inside.

To do this, you can mark the places for connecting the LEDs and the battery on the scan, and then install them in the process of gluing the layout.

Such a house can also serve as a night lamp, but in this case it is better to use a switching power supply that is connected to the mains.

A mobile phone charger will do. You can also use an inexpensive Christmas tree garland:

Simple layouts of houses without a sweep

These are, first of all, houses assembled with their own hands from paper cylinders. The same layouts are great for various small architectural forms on prefabricated landscape layouts.

But also using this technique, you can create a realistic model that imitates a log house so dear to the heart of any Russian.

To do this, you need to take longer pieces of paper for the manufacture of tubes, so that after folding its coils resemble the annual rings of a tree cut.

And the adjunction of the crowns can be modeled by crushing the ends of the tubes with a solid round object of a suitable diameter.

It is easy to assemble a paper frame from such elements. And bring out the intermediate crowns along the facades, and for a sample, you can take a photograph of any real log house.

It is better to make roof coverings of house models separately, in the form of paper slate sheets, tile flakes or honeycombs of bituminous tiles.

Dear readers, if you still have questions, ask them using the form below. We will be glad to communicate with you;)

Paper modeling can be classified as an occupation that will never cease to interest a person. Many orphanages of creativity necessarily organize design circles, because paper models not only provide an opportunity to get a new interesting figure or toy, but with their help you can improve your knowledge of physics and mathematics.

Tools for the job

To learn how to fold basic paper models, you will need simple tools like scissors, a utility knife, PVA glue, and a brush to apply it. Give preference to PVA construction glue - of all the varieties, it has the thickest consistency, it does not spoil the paper, making it wet and viscous, like a regular one.

Different models are folded from different types of paper - from cigarette to thick cardboard. Beginners are advised to start with 200g/m2 watercolor paper for large pieces and 140-160g/m2 drawing paper for smaller pieces.

Separate details, such as masts, railings, small finishing elements, are created by craftsmen from polymer clay, gypsum, plasticine and self-hardening plastic. If you also supplement your work with stucco parts, stock up on various stacks, molds - like those used in ceramic floristry.

How to make a paper model

The workflow for creating a paper model follows a few simple steps. Before starting the process, the master determines which figure he wants to design. In fact, almost any product can be made from paper, but paper modeling often involves the following options:

- geometric figures, polyhedra with convex and concave corners;

- scaled copies of famous buildings;

- models of luxury cars;

- models of military equipment: tanks, armored vehicles, heavy guns;

- vehicles: planes, ships and submarines, trains.

Figurines of a person, animals, plants are constructed much less often than others. Once the product category is defined, the main part of the workflow begins.

Creating a Layout

Three-dimensional models of paper are made up of several large and small details - the schemes of elements must first be drawn on paper sheets of the desired color. Here a person cannot cope without understanding certain knowledge of geometry and the possibility of representing a three-dimensional image.

To make it easier for beginners to learn, many specialized magazines began to issue drawings of finished scans for a paper model, by gluing which you can get a figure.

You also need to cut the layout according to the rules. For example, a solid line along the contour indicates the place of the incision, the dotted line indicates the fold. But in each scheme, the designations are individual, so before cutting out, you need to read the explanations for the figure.

Assembly

After the drawings of the paper model are ready, the layout is glued and finishing work is done, if necessary.

To make the surface of the product realistic, craftsmen use different coatings: glossy varnishes, matting sprays, craquelure liquids, stains, etc.

Paper car models

A beginner in paper modeling will enjoy this master class, which contains information on how to construct a well-known model of a VAZ 21011 sedan car in just half an hour.

Stock up on heavy drawing paper or coated sheet if the figurine is being made as a gift to a friend.

- On an A4 sheet using a color printer, print the finished scan of the paper model with your own hands. If you want to enlarge the scheme, make sure that the proportions of the length and width are preserved - changing the parameters may prevent the parts from joining correctly.

- Put a picture of a real car of this brand in front of you to use the picture as a guide when assembling. Bend the reamer in the right places.

- Give the blank the shape of a car to mark the gluing points for yourself. Only after that you can successively glue the white valves with glue and glue them to the necessary parts from the inside, fastening the parts of the machine to each other.

Please note that the tread strips need to be glued together, forming rings that will be attached to the wheels in order to get the most voluminous paper models.

paper tank models

The construction of military equipment out of paper is somewhat more difficult than the creation of civilian vehicles because the guns are made up of many small parts that form the body.

To see this, try to form a difficult, but very interesting model of the German Panther tank.

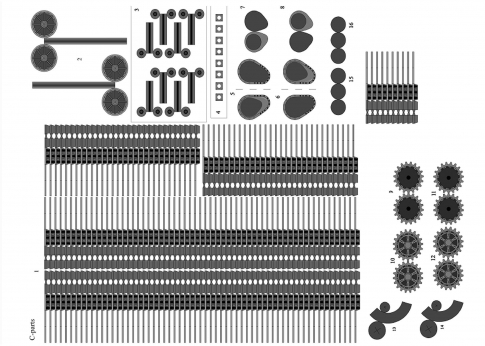

- On a thick A4 sheet, print out the drawings of the components of the tank using a color printer. Small details are best cut out of thin cardboard so as not to bend narrow curled elements.

- Cut out the pieces with sharp scissors to make the job easier.

- It is better to carry out gluing in blocks - separately connect the parts of the hull, propulsion system and turret, and then fasten large elements to each other.

To glue the parts of the tank in the correct order, follow this video tutorial when assembling.

Sometimes the joints are connected with small errors, due to which white paper stripes appear on the model. You can get rid of them with felt-tip pens or pencils similar to the color of the armor.

paper airplane models

If you already have some skills in building paper figures, you will surely enjoy building a paper and cardboard model of the Tu-104 passenger aircraft.

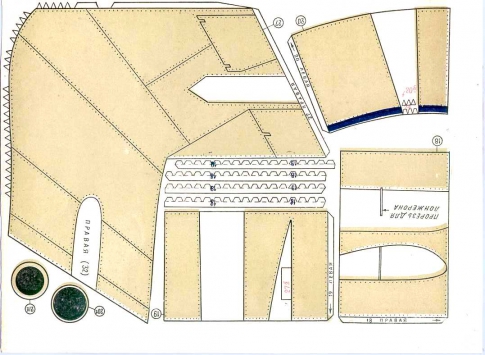

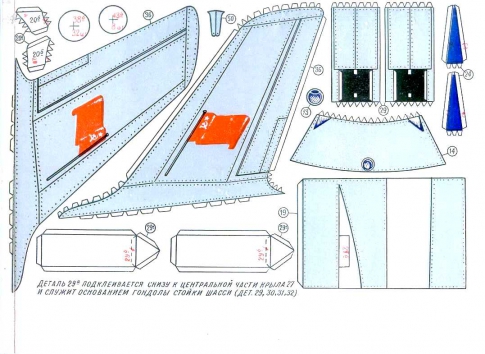

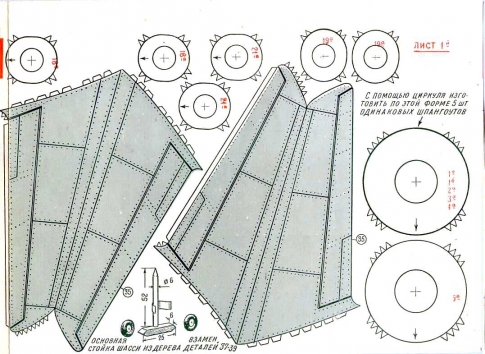

- Print out the aircraft drawings on thick paper.

- Stick the elements of the inner frame of the product on thin cardboard - they are marked with red numbers.

- Details marked with a cross - frames or frame - are transferred to cardboard using a compass. In this case, you can calculate the radius of the circle by placing the compass needle in the middle of the cross, and the pencil on the circle. Patterns of paper frames must be glued to these cardboard blanks.

- After developing the frame, start creating the fuselage, or body of the aircraft. Note that, unlike previous products, fuselage sections #1-8 do not have white fixing flaps. They are interconnected by special ribbons, represented on the patterns by the corresponding numbers in blue.

- The frames are glued into the joints between the fuselage sections.

- While the glue in the aircraft body dries, glue the tail parts together.

- The engines of the apparatus are assembled like a fuselage.

- Next, wings are formed using cardboard and paper.

- Connect the parts of the hull, wings, bow and cockpit together.

- The chassis assembly takes place in several stages - the wheels and their components are initially formed, after which the chassis is glued to the wings in a specially designated place.

- You can also use the pattern to cut out a wooden chassis - it will be stronger and last longer than paper and cardboard.

In order to avoid bends and creases on the body and tail, stuff the parts with cotton during the assembly process. Decorate the plane as desired with decoupage sprays and paints.

You can make a simpler model of an airplane out of paper with your own hands, focusing on this video.

Take it, tell your friends!

Read also on our website:

show more

Content

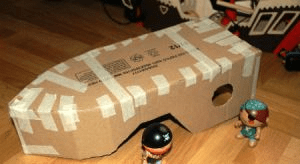

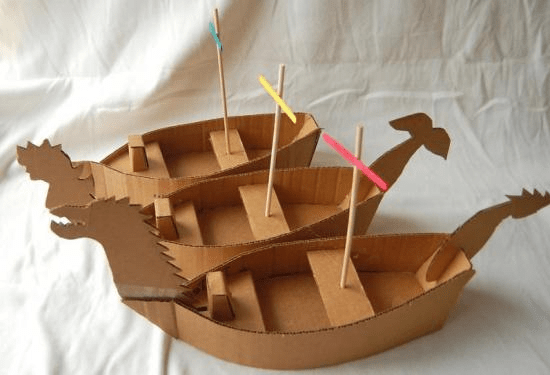

Recently, decor items that are made from recycled materials or from materials that are conditionally called garbage, for example, cardboard boxes from used appliances, have been in fashion. On the other hand, it has become fashionable to create various figures and models of equipment from paper. In this article we will try to create some interesting cardboard ship models. For some of these models, you will need ready-made templates, and some products can be created without diagrams, using your imagination. At the end of the article, you will definitely find a video tutorial that will help you consolidate your knowledge and create an interesting product from improvised means. Let's not waste time, prepare materials and start creating.

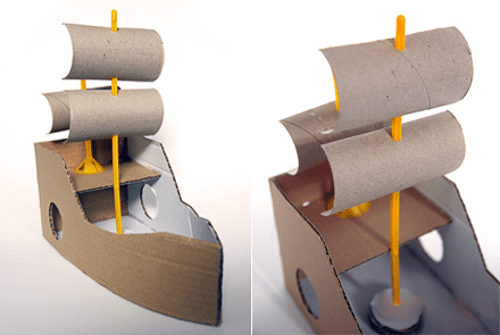

Templates

Let's first try to create a ship using templates. They are easier to work with. What you need:

- thick cardboard (you can use an old box);

- scissors;

- pencil;

- ready template;

- glue or tape;

- colored paper and other decor.

First you need to print the template and transfer it to the main material. By the way, if you are using not too thick cardboard, then the template can be printed directly on it.

You should get the following details:

Next, you need to dilute a little PVA glue with water, cut plain paper into pieces and stick them to the base of the ship by dipping them into the solution. Remember the papier-mâché technique. The parts of the ship themselves are best connected with adhesive tape.

It remains now to arrange the blank with a prepared decor. It can be colored paper, wrapping paper, fabric. The ship can also be painted with ordinary watercolors.

You also need to make a mast for the ship. You can use a regular twig and a few round logs made of thick cardboard.

Every ship should have a flag. For it, use a fabric and an application made of paper or material. The sail can also be made from cardboard, use toilet paper rolls.

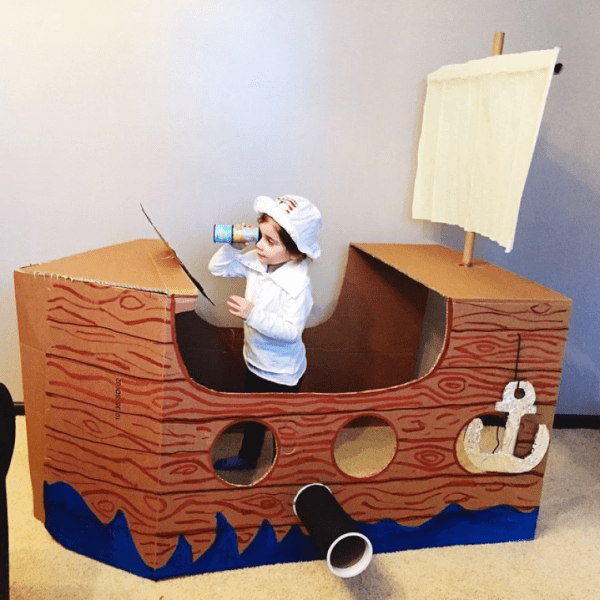

Making a big ship

This option is suitable for young children who love exciting games. For such a ship, you will need a large box. It can even be packaging from under the refrigerator or from a large TV.

First you need to connect the valves of the box and make a sharp bow of the ship. On the sides you need to cut out a few round timber to make impromptu portholes. Use a thick stick and fabric to make a flag. Use paint to paint the ship.

Do not forget about details such as the anchor - it also needs to be made of dense material and decorated. A large do-it-yourself cardboard ship is ready to sail through the vast expanses of the apartment.

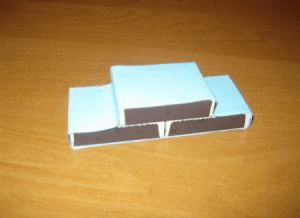

We use matchboxes

Let's call it modeling, because we will create a whole ship from several matchboxes. What will be required:

- cardboard;

- glue;

- matchboxes;

- wooden skewer or thick paper;

- colored paper;

- markers;

- scissors.

First you need to glue together two matchboxes with short sides. Glue another box on top in the middle.

Now you need to cut a rectangular piece of paper and glue it to the top of the structure.

Now you need to cut out a strip from thick colored cardboard, with which we will form the bow of the ship.

Now you need to cut out a piece of cardboard that will fit the contours of the ship, take a look at the photo:

Now the bottom and top of the ship need to be fastened with glue. Next, you need to make a mast. You can use a wooden skewer or twist the A4 sheet very tightly and secure the tip so that the sheet does not unwind.

A hole must be made in the upper matchbox of the ship so that the mast can be inserted. Don't forget to use glue.

Now it remains to cut out the sails from colored paper, paint them and attach them to the mast.

The matchbox ship is ready! It can be made wider and taller if more matchboxes are used. If you use very thick cardboard for the bottom of the ship, then it is quite possible to launch it on the water and participate in competitions for the title of the fastest ship.

DIY cardboard spaceship

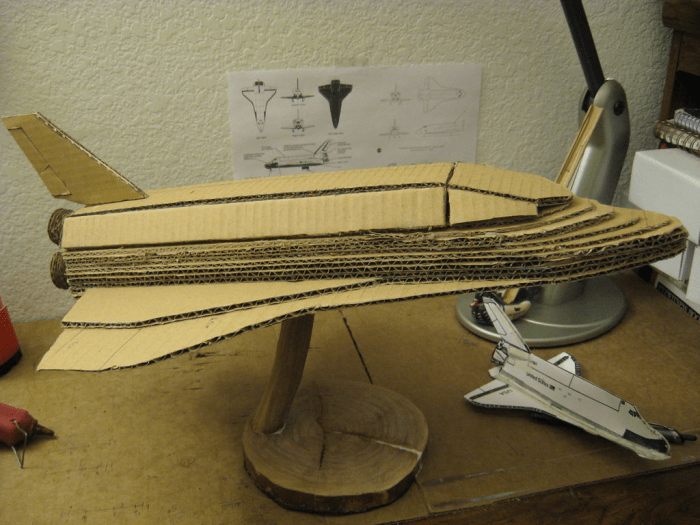

We suggest using a fairly simple option that will literally create a 3D model. To do this, it is necessary to cut out several identical parts from cardboard, but of different sizes. The parts must be fastened together, but laying between them either a thin piece of foam rubber, or a small piece of thick paper. It will turn out something like this:

Or like this:

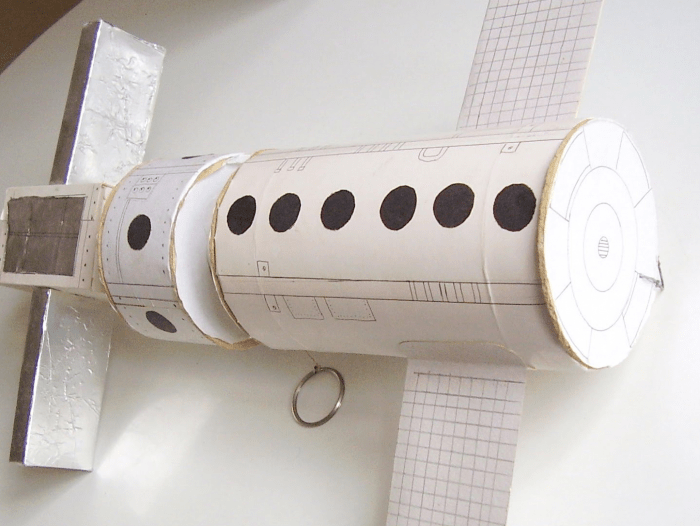

An entire space station can be made using cardboard toilet paper rolls and scotch tape.

Use silver foil, compasses, black felt-tip pen, and a simple pencil to give the spaceship a realistic look.

Cardboard is a fairly convenient and easy-to-use material, but if you know a few nuances, the work will seem even simpler, and the product itself will turn out neat:

- when working with very dense material, use rather sharp scissors, and even better - a clerical knife;

- before bending the cardboard parts, it is better to draw along the dotted lines with the non-sharp side of the scissors or an old pen that does not write, then the material will bend neatly and evenly;

- Not in all cases, you can use a glue gun. For example, if you are working with thin material, then it is better to use stationery glue or PVA;

- work in a room where the humidity is not too high, otherwise your products may delaminate or parts will not stick together;

- the room should be light, it is desirable that there is a window that can be opened and ventilate the room;

- and we always advise you to work only in a good mood.

How to make a ship out of cardboard with your own hands - a few more interesting options

We want to offer some more interesting and beautiful options for ships that you can do with your own hands.

In this case, a milk carton, cardboard boxes and a sleeve were used.

And this is a luxurious boat made from an ordinary cardboard box.

A little practice and imagination, and you can get such a beautiful do-it-yourself cardboard pirate ship. We always advise you to involve children in creativity. They will be especially pleased to know that they are creating a boat just for themselves. In parallel, you can think about a pirate costume, as well as make a spyglass, a hat and a cardboard knife out of cardboard. Such participation of children in creativity helps to develop their imagination, attentiveness, perseverance, the desire to create something with their own hands for themselves. Be sure to involve the children in cleaning as well. Explain to them that you need to put all the materials after yourself, put them in their places, and also clean up the workplace so that later you can get creative again.

An interesting type of creativity is the manufacture of paper and cardboard crafts. Often, both in kindergarten and at school, children are given the task of making some kind of paper craft with their own hands. From cardboard, such products are more solid, hold their shape well, and do not wrinkle. With such crafts, the child can play for a long time.

Boys love different equipment: cars, helicopters, planes, tanks. All this can be made from waste material, which is at hand in any home. This article will discuss how to make an airplane out of cardboard. Consider several different options, starting with the lightest product.

Flat plane made of cardboard according to the scheme

For such an air liner, you need to have a sheet of corrugated cardboard. You can use any hard cookie or shoe box. Using the diagram below, silhouettes of parts are drawn on a sheet with a simple pencil. Then carefully cut out each element along the contour with scissors. The inner hole can be cut with a sharp knife.

Before assembly, you need to apply a drawing to each part or paste it with colored paper. In the end, it just remains to put together all the elements. You don't even need to use glue or tape to do this. Do-it-yourself wing and tail of an airplane made of cardboard are simply inserted tightly into the main part of the structure.

Volumetric flying machine

To understand how to make an airplane out of cardboard, you need to carefully examine the photo of the craft. There is nothing complicated here. It is necessary to draw a drawing of all parts of the structure on cardboard: a body with a hole for the pilot, a wing, two parts for the tail and two wheels.

Parents can help with the diagram in this case by drawing details with a simple pencil, especially if the child is preschool or primary school age. Further, the boy can already make an airplane out of

The first part of the work is cutting out all the details along the contour with scissors. Then each can be either painted with gouache paints, or pasted over with colored paper. So that the paint does not stain the baby's hands while playing, all the details on both sides can be coated with acrylic varnish. It has no smell, dries quickly, and the plane will look brighter, the colors of the paints will appear more juicy.

At the end of the work, it remains to assemble the parts into a single whole. The wheels are put on a wooden or metal stick. If it does not work out, then you can simply glue them along the edges of the case. That's it, the cardboard airplane model is ready. You can play!

Airplane from a toilet paper cylinder

Before you make an airplane out of cardboard, you need to find: a solid cardboard tube left after using toilet paper, a sheet of corrugated cardboard, a simple pencil, scissors, a knife, a felt-tip pen or paints, a brush, a simple pencil.

In the tube, you need to cut a hole for the pilot, bending it forward. The next cuts for the wings and shank will be more convenient to make with a sharp knife. In the back for the tail, a hole can also be made with scissors.

The next step is to draw the details on a sheet of cardboard. These are two oval wings: long and short for the shank. Then you need to draw a triangular tail and round off its hypotenuse. The most complex part of the whole design is the front propeller. When the drawing is drawn up, all that remains is to cut out the elements and assemble the plane. It's already easy. The screw can be glued, or you can put it on a nail or paper clip, having previously glued the nose of the liner.

At the end of the work, the product is decorated. This can be done with paints, felt-tip pens, pasting with colored paper. It is already at your discretion.

big model

This version of the aircraft is the most time-consuming, and a small child is unlikely to be able to independently carry out this undertaking. The help of an adult will not be superfluous. If your baby is young, then this version of the technique can be made for games by parents or older children in the family.

First you need to have a large corrugated cardboard box. If parents recently purchased a refrigerator or washing machine, then the cardboard from the packaging can be used for this craft. Before you make an airplane out of cardboard, you need to consider the size of the future structure. If the box is large, and there are two children, then you can make the design long so that two pilots can sit down calmly at once.

Having cut off the extra parts of the box, they first make the body of the aircraft. You can try on by putting the baby there. Should be comfortable for the feet. Then work on the details begins. Since the model shown is a maize, there are two wings on each side, one above the other. They are fastened together with stops, representing structures in the form of the letter "I".

In order for both the wings and the tail to hold tightly, they need to be glued with strips of paper both from below and from above. You can use adhesive tape, gluing each part a couple of times. The screw is made of less thick cardboard in the form of an ordinary windmill. You can not install wheels, so the baby will have a stronger base and he will not fall. If dad or older brother makes such a model, the joy of the baby will exceed all expectations.

In order to creatively decorate the premises of the apartment, as well as add individuality to it, you can make cardboard furniture with your own hands, patterns and diagrams are so simple that even a beginner can make products. A variety of options will allow you to choose the right piece of furniture and make it, involving all family members in the process.

At first glance, you might think that cardboard is a fragile material that requires special handling. On the one hand, this is correct, on the other hand, by choosing the right kind of cardboard, you don’t have to worry about its further operation. Cardboard furniture will be durable and practical if you follow the sequence of work and recommendations for using tools.

To choose an option for self-manufacturing of furniture products, you need to consider several suggestions:

- Toy furniture made of cardboard - it is profitable and creative to make furniture for dolls on your own. If the children require the purchase of a new house for Barbie with all related accessories, the output will be the production of such an option with their own hands;

- Shelves for books - are considered one of the simplest cardboard products. It does not take much time to make them, and books do not put a lot of stress on cardboard;

- The original table - this will not be a dining table, on which dishes are constantly located, but a small coffee or coffee table. On such a piece of furniture, a child can perform developmental tasks, because it is designed for a small load;

- Chest of drawers - it is convenient to fold documents or papers into such furniture, children's accessories will also fit here. It is easier to make a chest of drawers from cardboard boxes from large appliances, such as a refrigerator;

- Shoe rack - an original shoe rack in the form of triangular cells will fit into any hallway. Entering the room, all guests will be surprised how convenient and practical the rack turned out to be;

- A small chair for children - since cardboard is not designed for heavy loads, furniture for children is what you need. A small chair for the baby will become his favorite subject, where he can draw or play.

As you can see, cardboard furniture is easy to perform. For its manufacture, you need the simplest material and a minimum of tools.

Shoe rack

toy

Necessary materials and tools

Regardless of which type of furniture is chosen for self-production, the list of materials will be the same. This necessarily includes the main raw material - cardboard.

To make the products durable, it is worth giving preference to three-layer cardboard. The quality of the material can be checked on the cut.

If a single-layer analogue was bought in advance, do not be upset. From this option, the manufacture of a dollhouse and furniture for dolls is good. If you use it for work on real furniture, you need to glue several layers of cardboard to give greater strength.

List of materials and tools for work:

- Scotch tape - it is better to purchase paper, plain and double-sided;

- Stationery or sharp construction knife;

- Scissors;

- Roulette and a long ruler;

- Pencil and stationery gum;

- Sandpaper - for cleaning cuts;

- Kraft paper;

- Glue - depending on the type of cardboard, you may need PVA, hot glue or Moment.

If all the listed materials and fixtures are prepared, it is worth moving on to the manufacture of the selected furniture. Experienced cardboard craftsmen recommend that beginners choose simple work to start, such as shelves or a table.

In order for furniture made by oneself at home to turn out not only beautiful, but durable, a number of rules should be followed. They will help to make high-quality products that will appeal to all household members:

- Gluing layers - when working with single-layer cardboard or to strengthen furniture, it is necessary to glue the material. When gluing cardboard together, try to lay the layers perpendicular to each other - this is how they give increased rigidity;

- The choice of glue - people who have already made furniture from this material are advised to use Moment glue. It does not get wet after application and instantly fastens the details of products. You can also purchase a glue gun and thermal sticks, which melt when heated, creating a glue trail;

- Why kraft paper is needed - kraft paper is used to paste over the edges and joints of furniture. With the help of such a move, the furniture looks neater. Before pasting, the joints are cleaned with sandpaper. It must be remembered that paper cannot be cut - it must be torn with your hands. So the layers will become smooth, without transitions;

- Features of cutting - during the manufacture of cardboard furniture, special attention is paid to cutting the material. Usually a clerical knife is used - it is important that it is always sharp, because the accuracy of the details depends on it. If thick cardboard cannot be cut, a jigsaw can be used.

Using a jigsaw, the work goes much faster. It is important to carefully cut the details and avoid mistakes, because the tool is too powerful for cardboard.

Cut cardboard with a knife

Choose the right type of cardboard

Use kraft paper

Choose your glue carefully

Step-by-step instruction

To make the production go quickly and not be accompanied by problems, there is a step-by-step instruction, a master class of cardboard furniture consists of a step-by-step description of each action. It begins with the creation of a drawing, then comes the formation of parts, their strengthening. The final stage is the assembly of furniture. Each of the stages must be considered separately.

Creating a drawing

The first thing to do is to draw a furniture drawing. To begin with, it is drawn on a regular A4 sheet in order to see a reduced version. In such a sketch, it is important to prescribe all dimensions and observe scaling. If you have the skill to work in special programs that allow you to develop product models, you should use them.

The first drawing should have an image of the product in a general three-dimensional view. Next, you need to draw a projection of the furniture with a top, side, back view separately. The next step will be the image of the details of the product: each detail must be drawn separately.

When the drawing is ready, it must be transferred to sheets of cardboard:

- Using a tape measure and a long ruler, draw on the surface of the raw material with a pencil, measuring the required dimensions;

- For work, you may need a square so that the corners of future furniture are even in the figure;

- When drawing on thin cardboard, try not to leave scratches with a pencil, and when making furniture from corrugated cardboard, draw clear and deep lines;

- It is necessary to cut the parts in compliance with all indents and possible margins of distance.

You can use ready-made patterns or come up with your own product that meets specific sizes and preferences.

Shaping parts

It is worth noting that when cutting out parts there should be no visible bends. If the work is done on a box from household appliances, it is better to cut on even edges. From six-layer cardboard, you can make do-it-yourself furniture with increased strength, for example, a bookcase for shoes or books.

Details of the product are formed using a sharp clerical knife. Masters advise using a construction knife if it is supposed to work with multilayer raw materials. As the knife becomes dull, its blade is changed. A dull knife will not be able to cut the necessary part evenly and along the contour - you will have to redo the pattern.

Depending on the type of furniture assembly, parts can be:

- Plug-in;

- glued;

- Stackable.

The latter option involves the gradual build-up of cardboard to achieve the optimal thickness. Such a move will further strengthen the model, preventing it from sagging under loads. It is advantageous to use cardboard sleeves in the design - special tubes with a high density. They are suitable for the production of legs for furniture, as well as for the assembly of structures in the original style. For example, a chair made of cardboard tubes looks creative and can support the weight of a person.

Plug-in

glued

Building

Strengthening structures

Each detail after cutting with a knife must be processed. This happens in the following way:

- Cleanup. The cut edges of the module must be sanded. This technique will give them smoothness and prepare for further processing;

- Pasting. For this, kraft paper is used. It must be torn with your hands, after which, using PVA glue, carefully paste over the edges. You can apply paper to the entire surface, which creates additional hardening.

Furniture assembled with grooves will be durable and reliable. In the photo below you can see the principle of manufacturing such furniture: in the process of patterning, oblong holes are additionally outlined, which are subsequently cut out. An additional structure is inserted into the grooves, which fastens the frame on both sides. Thanks to this, the furniture becomes stronger.

Often, stiffeners are used, which additionally fix the base of the furniture. With the help of them, you can independently strengthen the cardboard tabletop, shoe rack, bookcase. Stiffeners and grooves must be coated with glue. Having strengthened the structure, in the future you will not have to worry about the durability of the furniture.

Sand the surface

Wrap the surface with kraft paper

Assembly process

All prepared parts are glued together with a glue gun or Moment glue. If the assembly is carried out using grooves, they are also glued for strength. It is recommended to repair all irregularities on the surface of thick cardboard with putty - it will not leave marks, and the excess will hide under the finish.

Parts requiring gluing in layers must be placed under the press. Books or other heavy objects work well for this. After gluing, they are left for several hours, and preferably for the whole day, until completely dry. All resulting ribs must be masked with kraft paper. Gently glue the resulting corners to give them roundness. Then it's up to the small - decoration. There are several options:

- Decoupage - pasting with napkins;

- Acrylic painting;

- Wallpapering;

- Use of self-adhesive film;

- Decorating with mixtures.

Finished furniture can be used for its intended purpose within a day after production. Everyone can make cardboard furniture with their own hands, how to find patterns and patterns will be discussed below.

Applying glue to the floor

Pressing elements

We putty cracks